Tool & Die Mold Designer In South Africa Plastics

Innovative Die Material Solutions for Plastic Injection Moulding by ROVALMA

Based on 40 years of experience in tool materials and on the know-how of our dedicated scientists and technicians in the development, production and application of tool materials, ROVALMA has generated breakthrough die material solutions for many engineering applications. For the manufacture and usage of plastic injection moulding moulds and inserts, ROVALMA provides a comprehensive material solution package of different die material grades to respond to the diverse technical requirements of the different casting processes and optimization criteria of die designers, manufacturers, users and component buyers.

Rovalma is the inventor of the High Thermal conductivity Tool Steels. In 2006, while taking advantage of recently developed technologies and outstanding knowledge of tool steels, ROVALMA S.A. developed high thermal conductivity tool steels which feature thermal conductivities up to 70 W/m·K, combined with similar or even superior mechanical properties of conventional hot work tool steels. These type of tool steels have become rapidly appreciated by mold makers and components producers for the advantages that their high thermal conductivity provides in particular to:

- Decrease considerably the cycle time for both, reinforced and non-reinforced plastics

- Decrease considerably the scarps through fighting warpage and sink marks

- Make large and complex component geometries

- High performance Heat & Cool mould technology

Based on the industrial demands, a diversified range of these tool steels have been developed and provided to the plastic injection moulding industry.

For non-reinforced plastic, the grades FASTCOOL®-20 LH and FASTCOOL®-20 have been developed. Their main features are shown in the following table in comparison to standard P20 type steels:

For reinforced plastic, the grades HTCS®-130DC, FASTCOOL®-50, HTCS®-230 and HTCS®-233 have been developed. The following table presents their main features compared to the 1.2344 (H13) type steels. ROVALMA's HTCS®-230/233 tool steel grade is a revolutionary tool steel that can be hardened up to 50/52 HRc by a simple precipitation hardening treatment (aging), which allows to considerably cut down the lead time for die construction and to enhance tool durability through a homogeneous distribution of the tool properties along the different tool sections, while featuring outstanding dimensional stability during hardening:

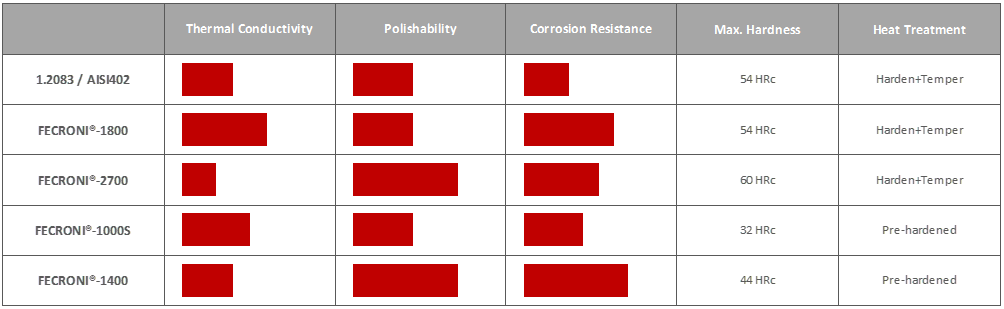

For corrosive plastics and applications for which a stainless tool steel is required, ROVALMA developed the high performance FECRONI® grades. FECRONI® grades are produced and refined by using the latest production technology for melting, forging and thermal processing to obtain the highest possible level of purity, isotropy, refined microstructure, corrosion resistance fracture toughness and polishability. Moreover, some grades have been homologated for food contact. The main features of these grades compared to the conventional EN/DIN 1.2083 / AISI420 steel are presented in the following table:

Tool & Die Mold Designer In South Africa Plastics

Source: https://rovalma.com/application/plastic-injection-moulding-other-plastic-forming-processes/

Posted by: mckinnongreaboy.blogspot.com

0 Response to "Tool & Die Mold Designer In South Africa Plastics"

Post a Comment